Stronger and Better! Here's why...

LIGHTWEIGHT STEEL HITCHES

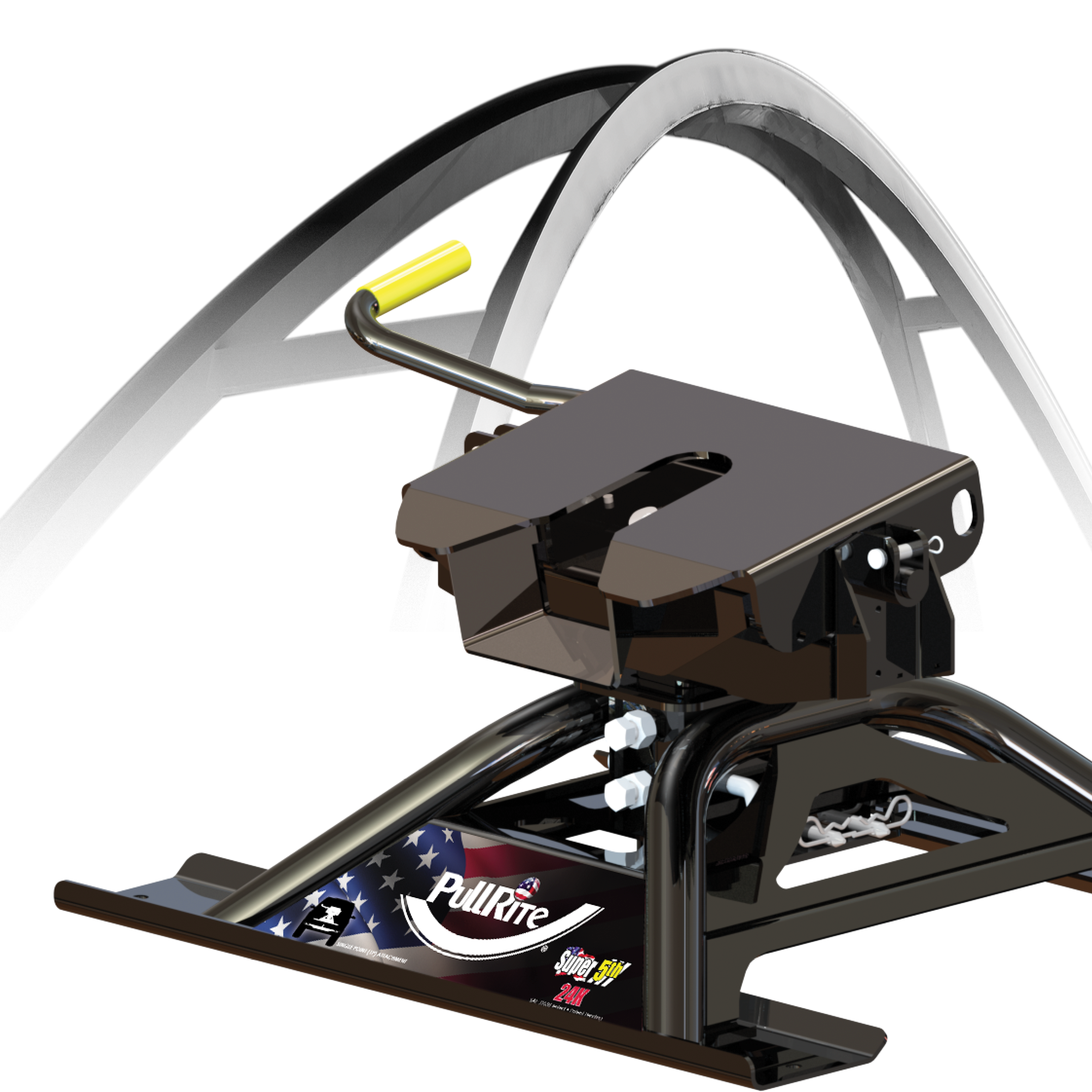

How can PullRite #3900 Single Point Attachment steel hitch be lighter than it's competitor, but still pack a higher weight rating of 24K?

Our team of engineers have used just the right amount of steel and support where it is needed. All our fifth wheel hitches that use a SuperLite arched base, like #2400, #2600 and #3900 hitches, are based off a proven design that has been used for centuries...the tied arch bridge.

Known for their superior strength and lightweight design, the inward slanting arched ribs on tied arch bridges are optimized to take the stress of large loads and distribute it evenly to its base.

PullRite's engineers incorporated this design to provide our customers with a truly lightweight, but strong connection between their truck and trailer.

LIFTING WEIGHT

Lifting weight is also an important factor that we consider. Not everyone can move a hitch by themselves when you consider how heavy they can be.

The #3900 hitch pictured here not only has the lightweight, arch base, but a removable head that require no tools to remove, lightening the load by 40 lbs.! And since the #3900 and #2600 models use our Bed Saver Rails that aren't fixed to the hitch, you don't have to lift those either.

Another great feature of PullRite's #3900 and #2600 Single Point Hitches, when compared to a popular gooseneck-mounted hitch (see comparison here), is they mount to any standard height 2-5/16" gooseneck ball or even OE gooseneck balls. Our competitor's hitch only works with their proprietary underbed gooseneck system.

And because the gooseneck ball setup isn't attached to a PullRite hitch like the competitor's hitch mentioned above, but rather mounts over it, extra weight is eliminated. Lifting weight isn't a problem and there's no struggle trying to lift it straight up out of the gooseneck receiver tube like the competition's...as you can see in the video below...it's definitely a two man job.

SAE TESTING

We want to produce a great product for you that meets your expectations for safety and reliability, and we've done that through the rigorous testing laid out by the SAE J2638 standard, as well as our own additional testing.

We want to produce a great product for you that meets your expectations for safety and reliability, and we've done that through the rigorous testing laid out by the SAE J2638 standard, as well as our own additional testing.

SAE tests consist of dynamic and static loads placed on the hitch in tension and compression vertically, horizontally (sideways) and longitudinally (front-to-back). In addition, we perform real road testing with exaggerated stops and starts, sharp turns, etc. Essentially, we try to break it so you never have to!

Because we operate within these strict guidelines when manufacturing and rating our hitch's GTW (Gross Trailer Weight), we can be confident that our products will stand the test of time and give you peace of mind when towing.

You can read much more about our testing procedures that not only meet, but often exceed, the SAE J2638 standard by clicking here.