OE Puck Gooseneck Ball -- How it Works!

It may seem like an insignificant item, but the gooseneck ball is the FIRST and ONLY connection your hitch and trailer has to your truck, so it should stand out from all the rest as being reliable, innovative, and manufactured with the very best materials to keep you and your family safe, right?

It may seem like an insignificant item, but the gooseneck ball is the FIRST and ONLY connection your hitch and trailer has to your truck, so it should stand out from all the rest as being reliable, innovative, and manufactured with the very best materials to keep you and your family safe, right?

Truck manufacturers introduced their Tow Prep Packages a few years back and their popularity spread like wildfire. These underbed mounting systems keep the bed clean when you’re not towing by utilizing four mounting points in the bed and a center mounting socket.

While we weren’t the first manufacturers to come out with a gooseneck that fit into a single point system, that did give us an opportunity to observe the market and see what RV’ers were saying and problems they were experiencing. And, sure enough, we did find some complaints out in the field. What we found was the opening in the top of the ball allowed debris to enter the locking system, and all too often, making it fail to operate. The other issue we ran across was the ball freezing into the OE socket in cold weather or from corrosion, without a way to remove it once it was frozen in place. The last issue was theft.

So we set out to improve on as many areas as possible. But first, watch this short video and then we'll go into more detail...

NO OPENING ON THE TOP OF THE BALL

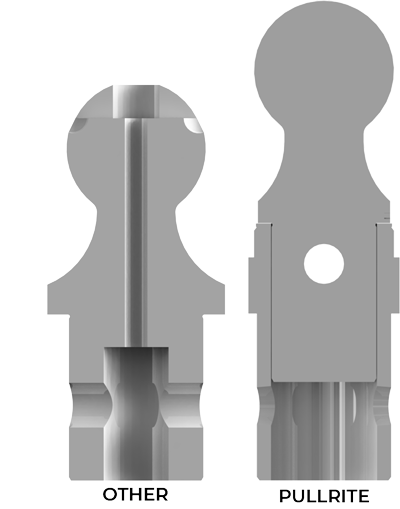

Probably the most important feature of our Gooseneck Ball is the fact that it is just that, a ball. Nearly every other ball on the market has a locking mechanism that is operated from the top of the ball through a shaft or hole that runs the length of the ball.

Probably the most important feature of our Gooseneck Ball is the fact that it is just that, a ball. Nearly every other ball on the market has a locking mechanism that is operated from the top of the ball through a shaft or hole that runs the length of the ball.

The top of the ball is frequently exposed to dust, debris, weather and moisture; when you’re out RVing, it’s also covered in grease, so naturally, organic debris and dust will collect there. If you have a hole running the length of your ball, from top to bottom, there’s no way to prevent all that debris from finding its way inside and gumming up the works.

We designed and patented our OE Gooseneck Ball with no openings in the top. The locking mechanism is engaged by twisting the ball, which activates the lock within the Gooseneck Ball Post. So even if debris does collect, with ours, you just wipe it off and it’s clean and operable.

A SOLID GOOSENECK BALL

Another advantage of not having any openings or locks to engage in the ball itself, is we are able to provide you with a solid, zinc coated ball that is durable and corrosion resistant. Because other manufacturers have designed their locking mechanisms to be on the top of their ball and drilled down through the center (plunger type lock as seen in the cross section illustrations here), which means their ball is hollow compared to our solid ball. Which one would you rather tow with?

With a PullRite ball, you not only have a strong, solid piece of metal your rig can attach to, but you can rest assured that is the case because ours is thoroughly tested and exceeds SAE J2638 standards.

SAE TESTING

SAE International (the Society of Automotive Engineers) is a U.S. based and globally active association of engineering professionals in various industries, but primarily automotive. Their goal is to solve common technical design problems and develop engineering standards that help protect the consumer and manufacturer through their prescribed methods of testing.

We put all our hitch products through a series of dynamic and static loads according to SAE test requirements that reveal how our products will hold up to the extremes of RV’ing and we are able to apply a true, maximum tow capacity.

Its important to us that we go to these lengths to ensure the quality and reliability of all our products. You can learn more about the importance of SAE Testing by clicking here.

CORROSION RESISTANCE

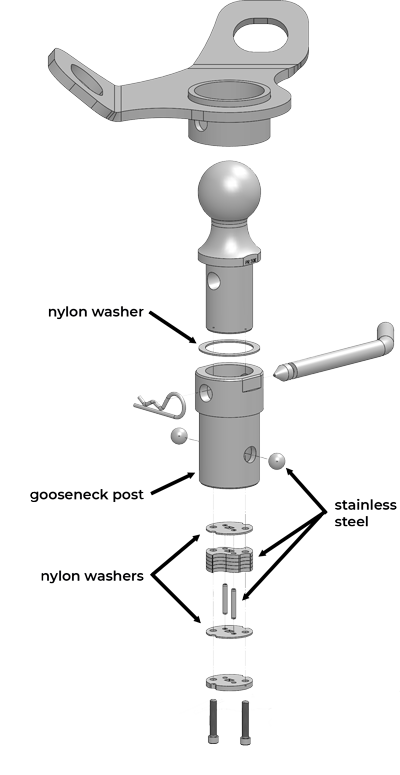

Though we’ve minimized access points for moisture to find its way into our ball’s working mechanism, we knew there must be a preventative measure added to resist binding of the moving parts and overall corrosion. Metal-to-metal contact is a real issue as it promotes corrosion.

So for the exterior, we chose a zinc plated, mild steel that would resist corrosion much longer than a chrome plated ball would. But a mild steel exterior touching internal stainless steel parts would still cause corrosion and binding.

To avoid all this, as you can see in the illustration here, we separated all metals that weren’t alike with nylon washers to prevent them from touching one another, and even designed the internal locking plates in such a way that they don’t even touch the sides of the Gooseneck Ball Post sides or the end cap.

THEFT DETERRENT

We have addressed the third issue, theft, by designing a simple cross pin to lock the ball mechanism into the puck socket, providing a means to secure it with a padlock.

We have addressed the third issue, theft, by designing a simple cross pin to lock the ball mechanism into the puck socket, providing a means to secure it with a padlock.

Click here for more information on the #2621 OE Gooseneck Ball Security Kit.

AMERICAN MACHINED PARTS & TIGHT TOLERANCES

During the recession in 2008, we made a company-wide decision that we would keep our manufacturing here in America no matter the outcome. Ten years later, we still stand by our commitment to keep and create American jobs. It means a lot to us and we know it does to many others as we see our manufacturing coming from overseas. If you ask the right questions, you’ll find that most other hitch brands come from China. Because our products are made in our own factory, we are able to keep a watchful eye on tolerances and the machining of our products.

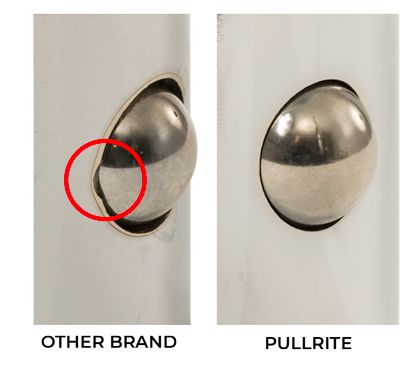

A good example of that can be seen in the way we set our stainless steel ball bearings into place in the Gooseneck Post.

If you look closely here at the competitor’s ball bearing in the picture to the right, it is kept in place by a process called “staking.” This is a quick and inexpensive method for a manufacturer to hold the ball bearing in place. A small piece of metal is gouged out over the drilled hole to hold the ball in place. That gouged and bent piece of metal is the only thing that “holds” their bearings in place.

If you look closely here at the competitor’s ball bearing in the picture to the right, it is kept in place by a process called “staking.” This is a quick and inexpensive method for a manufacturer to hold the ball bearing in place. A small piece of metal is gouged out over the drilled hole to hold the ball in place. That gouged and bent piece of metal is the only thing that “holds” their bearings in place.

That didn’t sound very reliable to us, so we went a step further. We chose to go with a more reliable method of drilling a cone-shaped hole into the wall of the gooseneck ball post, instead of staking. This prevents the ball bearings from ever coming out of their housing.

And to keep the operation of engaging the lock by turning as smooth and free of binding, we manufacture our own stainless steel plates that cradle

and keep the bearings moving smoothly in and out of place perfectly.

Should the rare occurrence of binding happen, whether due to freezing, debris, poor maintenance, etc., we have machined “flats” into both the ball and shaft that you can easily turn with a pair of pliers. These flat areas on either side of the OE Gooseneck ball allow you to turn either the ball to activate the locking mechanism or the shaft to release it from its mounting point should it become lodged.

Should the rare occurrence of binding happen, whether due to freezing, debris, poor maintenance, etc., we have machined “flats” into both the ball and shaft that you can easily turn with a pair of pliers. These flat areas on either side of the OE Gooseneck ball allow you to turn either the ball to activate the locking mechanism or the shaft to release it from its mounting point should it become lodged.

OE SERIES SAFETY CHAIN PLATE

Why do you need a chain plate at all? Safety.

Prior to OE Puck Systems hitting the market, nearly all aftermarket underbed gooseneck balls had their safety chain anchors over the gooseneck ball with just enough chain length to attach safely. Now with Four Point (4P) systems, you are in need of longer lengths of chain that are necessary to reach the mounting points where they want you to anchor them. This means you would also need to purchase a longer length of chain, and possibly do some welding to attach it to your trailer.

These attachments points take you further away from the trailer’s center attachment point and in the case of a Ram OE Tow Package, the pucks are a considerable distance away. From our perspective, that’s not a good idea at all and comes with some potential problems.

These attachments points take you further away from the trailer’s center attachment point and in the case of a Ram OE Tow Package, the pucks are a considerable distance away. From our perspective, that’s not a good idea at all and comes with some potential problems.

The Safety Chain is there to restrict its movement in the bed of your truck before you get stopped should you drop your trailer. Now, a more seasoned RV’er knows that if he does drop his trailer, the last thing you want to do is slam on your brakes. That would then propel the trailer forward toward the cab and cause damage, but even if you did out of a knee-jerk reaction, because the safety chain is the proper length and is attached at the center of the truck, the likelihood your dropped trailer would hit your cab or bedsides is greatly reduced.

The Safety Chain is there to restrict its movement in the bed of your truck before you get stopped should you drop your trailer. Now, a more seasoned RV’er knows that if he does drop his trailer, the last thing you want to do is slam on your brakes. That would then propel the trailer forward toward the cab and cause damage, but even if you did out of a knee-jerk reaction, because the safety chain is the proper length and is attached at the center of the truck, the likelihood your dropped trailer would hit your cab or bedsides is greatly reduced.

Now with the 4P systems on the market, you have manufacturers asking you to install their safety chain anchors into one of the four mounting points in the truck bed. This moves the anchor point away from the center of the bed, and a standard trailer safety chain is not likely to be long enough to anchor into one of the pucks. So now you will be required to go out and buy a longer chain, and you may have to deal with some welding and/or possible trailer modification to make those puck mounted chain anchors work.

Moving the safety chain away from the center of the bed and putting it on a longer “leash” increases the diameter of movement the dropped trailer can move in, causing damage to cab, bedsides, tailgates, etc. We keep that safety chain centered to the bed over the ball reducing the area that dropped trailer has to inflict damage to your vehicle.

Sometimes, newer is not always better, and we believe that is the case here with puck mounted safety anchors. We keep the attachment points closer to the ball where it belongs and use the trailer manufacturer’s supplied chains.

Lastly, like all our products, the OE Safety Chain Plate is made from strong, American steel and you can be assured that we have put your safety first. Quick and easy to install with just a pin and clip, this Chain Plate is like no other. The #4437 OE Series Gooseneck Ball comes with a Safety Chain Plate.

CONCLUSION

So why choose the OE Series Gooseneck Ball? Three main features for you to consider is 1) no opening at the top of the ball. Other manufacturers are using plunger type locking mechanisms that gouge out a channel for their lock to be engaged. There is nothing stopping dirt, debris and a great deal of water to get down into their working mechanisms. Corrosion and binding occur much quicker and you’re going to have trouble with them breaking down. 2) We prevent different types of metals from contacting one another that helps to prevent corrosion, and where we need metal-to-metal contact, we use stainless steel and plastic washers (not plastic parts that grow brittle and break quicker than metal). 3) We have the only Gooseneck Ball on the market that can be locked down to deter theft.

We have subjected this and all our products to rigorous SAE J2638 testing and you can be sure that we have applied the accurate tow capacity ratings. Not all manufacturers test to the same standards and often times than not, they only perform static testing.

Our test rigs perform not only static (up and down) stress tests, but dynamic stress tests where horizontal (side-to-side) and longitudinal (front-to-back) forces are applied over a period of 300,000 cycles in each of the three directions. That’s over 900,000 cycles total.

We stand out because we go farther than the average manufacturer. Our staff and owners are RV’ers themselves just like you, so they’re concerned about their safety and yours. We want you to have the best RV experience possible and are here to help you have the best RV’ing experience possible!

Now that we've talked about it, let's watch it in action in this short clip!